Add to Cart

| Attribute | Value |

|---|---|

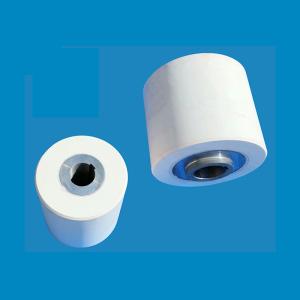

| Material | 95% Alumina Ceramics |

| Color | White |

| Heat resistance level | High heat resistance |

| Shape | Customizable |

| OEM,ODM | Acceptable |

| Origin | WUXI JIANGSU CHINA |

| MOQ | 100 PCS |

| Package | Carton |

Alumina ceramics have excellent properties and can be widely used in a variety of harsh environments. The excellent hardness and toughness of alumina ceramics make it a key material for the production of bulletproof armor. It is used in body armor plates and vehicle armor to protect against bullets, shrapnel and other projectiles.

| Naterial | Unit | A95% Alumina Ceramics | A97% Alumina Ceramics | A99% Alumina Ceramics | A99.7% Alumina Ceramics |

|---|---|---|---|---|---|

| Density | g/cm³ | 3.6 | 3.72 | 3.85 | 3.85 |

| Flexural Strength | Mpa | 290 | 300 | 350 | 350 |

| Compressive Strength | Mpa | 3300 | 3400 | 3600 | 3600 |

| Modulus of Elasticity | Gpa | 340 | 350 | 380 | 380 |

| Impact Resistance | MPam1/2 | 3.9 | 4 | 5 | 5 |

| Weibull Modulus | M | 10 | 10 | 11 | 11 |

| Vickers Hardulus | HV0.5 | 1800 | 1850 | 1900 | 1900 |

| Thermal Expansion Coefficient | 10-6K-1 | 5.0-8.3 | 5.0-8.3 | 5.4-8.3 | 5.4-8.3 |

| Thermal Conductivity | W/Mk | 23 | 24 | 27 | 27 |

| Thermal Shock Resistance | △T℃ | 250 | 250 | 270 | 270 |

| Maximum Use Temperature | ℃ | 1600 | 1600 | 1650 | 1650 |

| Volume Resistivity at 20℃ | Ω | ≥1014 | ≥1014 | ≥1014 | ≥1014 |

| Dielectric Strength | KV/mm | 20 | 20 | 25 | 25 |

| Dielectric constant | εr | 10 | 10 | 10 | 10 |